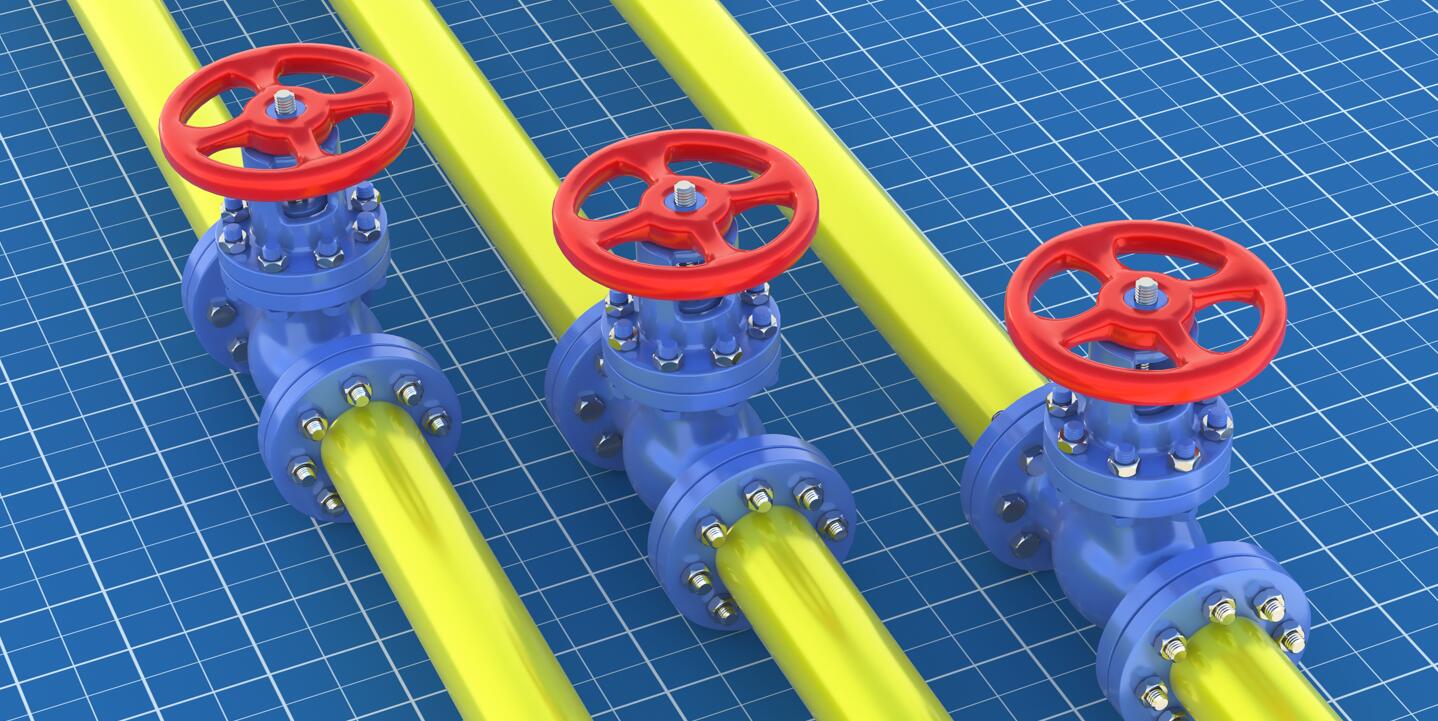

Gas valves, as key components for controlling gas flow, play an important role in industrial, commercial, and household applications. Their basic working principle and operation mode are crucial for the normal operation of various systems. In this blog, we will delve into the basic working principles of gas valves, from how to control gas flow to different types of gas valves and their applications.

What is a gas valve?

A gas valve is a mechanical device used to control gas flow. They can be turned on, off, or adjusted for gas flow in the system to meet different needs. There are various types of gas valves, including ball valves, butterfly valves, plug valves, safety valves, etc. Each valve has unique characteristics and applications.

The basic working principle of gas valves

The basic working principle of a gas valve is to control the flow of gas by changing the shape or position of the internal channels of the valve. The following are the main points of the working principle of gas valves:

1. Valve body and disc

Gas valves usually consist of two parts: the valve body and the valve disc. The valve body is the outer shell of a valve, used to secure the valve disc and connect it to the pipeline system. The valve disc is the movable part inside the valve, which can rotate up and down or inside the valve body.

2. Opening and closing

During operation, the valve disc can be moved, thereby changing the state of the gas channel. When the valve disc is in the open position, gas can freely flow through the valve, enter or leave the pipeline system. When the valve disc is moved to the closed position, the gas channel is closed, preventing gas flow.

3. Adjusting the flow rate

In addition to opening and closing, some gas valves can also be used to regulate gas flow. These valves typically have special designs that allow the valve disc to partially open to control the gas flow rate. By changing the opening of the valve, the gas flow can be adjusted to meet the needs of the system.

4. Drive mechanism

The operation of gas valves usually requires a driving mechanism, such as manual operation, electric operation, or pneumatic operation. Manual operation is achieved by manually rotating or moving the valve disc, while electric and pneumatic operations rely on electric motors or compressed air to control the movement of the valve.

Different types of gas valves and their working principles

Now let’s learn about some common types of gas valves and their working principles:

1. Ball valve

Ball valve is a common gas valve that uses a spherical disc to control gas flow. When the valve disc rotates, the gas channel can be fully opened or closed. The working principle of ball valves is very simple and easy to operate, making them widely used in many applications.

2. Butterfly valve

Butterfly valves use a disc shaped disc that rotates inside the valve body to control gas flow. The advantage of butterfly valves is their simple structure, fast opening and closing, and suitability for high flow gases.

3. Plug valve

Plug valves use a rotating cylindrical shaped disc with holes inside to control gas flow. Plug valves can achieve precise flow regulation and are suitable for applications that require high-precision control.

4. Safety valve

A safety valve is a special type of gas valve used to release gas when the gas pressure in the system exceeds the set value, in order to prevent system explosion or damage. Their working principle is that when the gas pressure rises to the set pressure, the valve will automatically open and release the gas.

Environmental and sustainability considerations

Finally, let’s consider how the working principle of gas valves is related to the environment and sustainability. Proper selection and operation of gas valves can reduce gas leakage, improve system energy efficiency, reduce carbon emissions, and thus have a positive impact on the environment. Through appropriate maintenance and regular inspections, the long-term stable operation of gas valves can be ensured, reducing waste of resources.

conclusion

Gas valves, as key components for controlling gas flow, play a crucial role in various applications. Understanding the basic working principles of gas valves helps us better understand their functions and applications in the system. By selecting, operating, and maintaining gas valves correctly, we can reduce gas leakage, improve system energy efficiency, reduce negative impacts on the environment, and achieve more sustainable industrial and commercial operations. I hope this article can help you gain a deeper understanding of the working principle of gas valves and their importance in various applications.