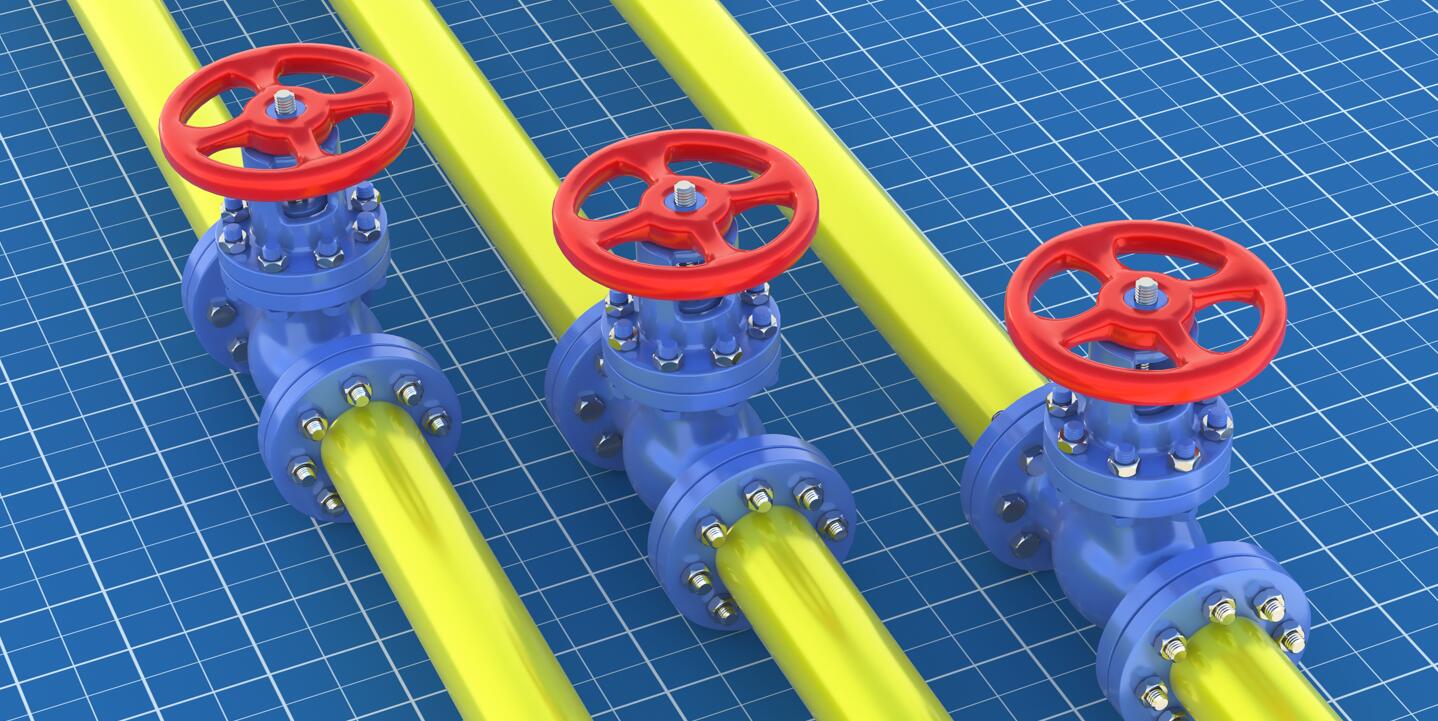

Gas valves play an important role in industrial, commercial, and household applications, used to control gas flow and maintain normal system operation. However, to ensure the long-term reliability and safety of the valve, regular maintenance and upkeep are required. In this article, we will delve into the maintenance and upkeep of gas valves, as well as the best practices for performing these tasks.

Why is maintenance and upkeep important?

Maintenance and upkeep are crucial for gas valves for the following reasons:

a. Extend lifespan

Regular maintenance can extend the service life of gas valves. Valves are key components in the system, and prolonged maintenance may lead to wear, corrosion, or other damage, reducing their lifespan.

b. Ensure reliability

Valve failure may lead to system shutdown, resulting in production interruption and losses. Maintenance and upkeep can help ensure reliable operation of valves at critical times and reduce potential production interruptions.

c. Reduce leakage risk

Gas leakage not only damages resources, but may also pose a threat to the environment and employee health. Regular inspection and maintenance can reduce the risk of leakage.

d. Improving energy efficiency

A well maintained valve is usually more efficient than an unmaintained valve. By ensuring the normal operation of the valve, the energy consumption of the system can be reduced.

Maintenance and upkeep steps for gas valves

The following are the general steps for gas valve maintenance and upkeep:

a. Visual inspection

At the beginning, conduct a comprehensive visual inspection to check if the appearance of the valve is normal. Look for possible signs of corrosion, damage, leakage, or foreign objects.

b. Cleaning

Regularly clean the valve to ensure that its moving parts are free of debris or deposits. Use appropriate solvents and tools, such as brushes or air guns, to remove dirt.

c. Lubrication

The moving parts of the valve may require regular lubrication. Ensure the use of appropriate lubricants to prevent friction and wear.

d. Testing

Conduct functional testing of the valve, including opening and closing operations, to ensure its normal operation. Check if the sealing performance of the valve still meets the requirements.

e. Replace worn parts

If necessary, replace worn or damaged components in a timely manner. This can prevent further damage and ensure the normal operation of the valve.

f. Calibration

If the system requires high-precision control, regularly calibrate the valve. Calibration can ensure the accuracy and reliability of the valve.

g. Leak detection

Perform a leak test to confirm if the valve is leaking. Use gas detection instruments or soap water solutions to detect potential leakage points.

h. Record Maintenance Record

Records of maintenance and upkeep are very important. Record the date of each maintenance, maintenance content, and identified issues. This helps to track the performance of the valve and develop further maintenance plans.

Frequency of maintenance and upkeep

The frequency of maintenance and upkeep depends on multiple factors, including valve type, usage conditions, and environment. Generally speaking, valves that are frequently used require more frequent maintenance. Here are some general guidelines for maintenance frequency:

Regular maintenance: Perform basic maintenance and inspections every 3 to 6 months.

Mid term maintenance: Conduct detailed maintenance every 1 to 2 years, including lubrication and component replacement.

Comprehensive maintenance: Conduct comprehensive maintenance every 3 to 5 years, including calibration and sealing performance testing.

Professional maintenance services

For complex gas valves or applications that require high precision, it is recommended to hire a professional maintenance team for maintenance and upkeep. A professional team with experience and tools can ensure the optimal performance and safety of valves.

Conclusion

The maintenance and upkeep of gas valves is a key step in ensuring the reliability and safety of system operation. By regular inspection, cleaning, lubrication, and testing, the lifespan of the valve can be extended, the risk of leakage can be reduced, energy efficiency can be improved, and production interruptions can be avoided. Remember, maintenance records are crucial as they can help you track valve performance and develop appropriate maintenance plans. Finally, for complex gas valves, it is recommended to seek professional maintenance services to ensure the optimal performance and safety of the valve.